COMPONENTS

BODYFRAME

ANVILS

ROTOR

SHAFT

HAMMERS

BEARING HOUSING

BEARINGS

FEEDING CHUTE

HYDRAULIC ACTUATORS

DRIVING GROUP

TIP SPEED

DESCRIPTION

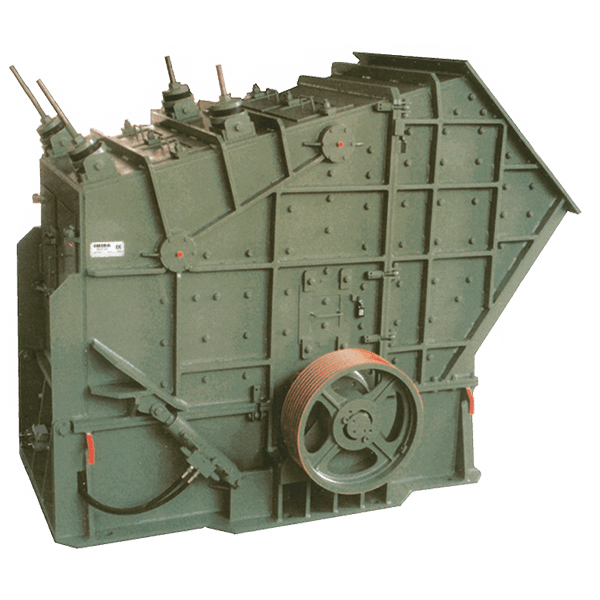

The primary impact croushers type “PK” are designed to break the raw material by means of a sequence of violent strokes, direct and indirect, inside a crushing chamber. The material, entering along a feeding slide, is repeatedly hit by a set of special steel bars located along the generatrix of a cylindrical body revolving at high speed: the produced fragments, in their turn, are hurled against two periferal anvils, armoured by special wear-resistant steel plates, which are causing a further comminution.

The inclination of the anvils is adjustable in order to allow to enlarge or to reduce the opening for the passing materials, thus forcing more or less strongly the crushing process and shaping the products as cubical as possible. Furthemore, the anvils being pivoting around their own supports, they are allowing a way out to any uncrushable junk occasionally entrapped into the crushing chamber. By virtue of this operational principle it is possible to reach very high reduction ratios (1:10 and even more), with evident economic benefits in terms of capital investment.

Being conceived as primary crushers, the “PK” line units are not equipped with the sizing grate and, therefore, the outgoing material does not avail of a given size on its own: a proper recycling closed loop may solve the problem. These crushers can not be used for processing wet or soft materials (like wood, plastic, rubber, clay or similar), nor highly abrasive materials, because in the latter case the cost of the resulting wears might not be economically justified.

DOWNLOAD PDF

For more information or to request the product pdf write at this email address info@imisa1922.com