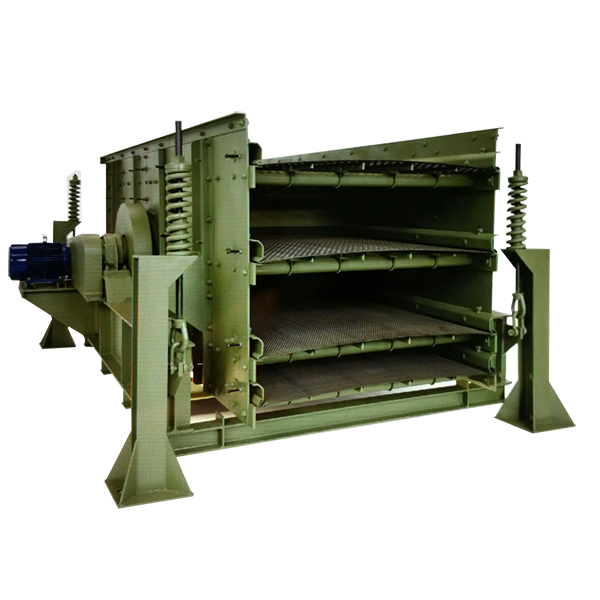

ADVANTAGES OF THE ECCENTRIC SHAFT TYPE VIBRATING SCREENS COMPARED TO THE CONVENTIONAL SCREENS

VIBRATING CASE

BASE FRAME

SCREENING DECKS

Apertures available from 500 microns up to 80 mm.

SUSPENSION

MECHANICAL DRIVE

ECCENTRIC SHAFT

BEARINGS

CASE SPRIGS

OPTIONAL DEVICES

DOWNLOAD PDF

For more information or to request the product pdf write at this email address info@imisa1922.com